Calculating How Much Concrete Pigment You Need

Freshly poured concrete gives designers and homeowners unlimited color possibilities for designing gorgeous concrete floors, countertops, and patios. Concrete pigment powder is pre-formulated to color cement, resulting in a fade-resistant, even color tone throughout the freshly poured slab.

Customers building homes or undergoing major home renovations often ask us “How To Pour Concrete Slabs With Color,” and commonly have questions about how to use Direct Colors’ concrete pigment with concrete countertops.

While adding concrete coloring pigment to fresh concrete during mixing is as easy as mixing flour and water, customers must first answer a few important questions to get the best color and appearance for their slab.

How Much Pigment Do I Need?

Follow all steps and questions listed below to determine the exact amount of concrete pigment necessary to color your slab.

For exact PSI and fly ash specifications, contact the ready-mix cement company responsible for pouring your concrete, then use the Direct Colors Calculator to choose one of the hundreds of Direct Colors’ pre-formulated colors found on our Color Chart.

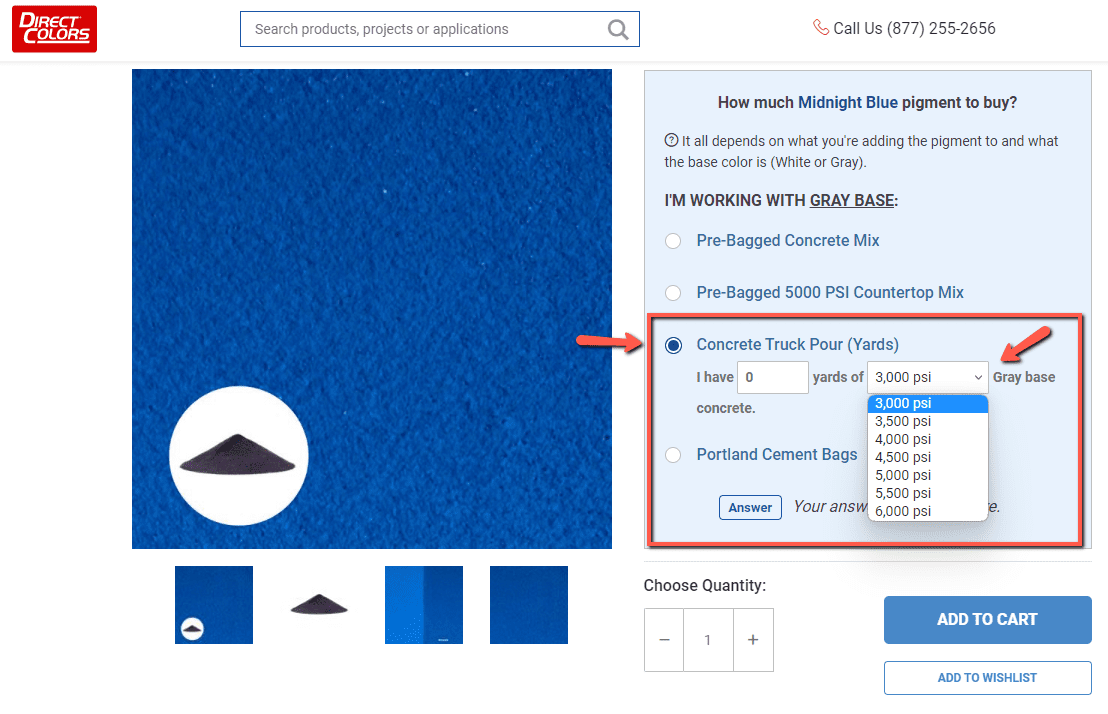

What PSI is My Concrete?

The strength of most concrete slabs is either 3000 or 3500 psi and this represents the amount of cement contained in each poured yard of concrete.

Determine the PSI, or “sack mix,” of your concrete by contacting the cement company beforehand. This is the crucial first step to calculating the amount of pigment needed for any strength from 3000-6000 psi.

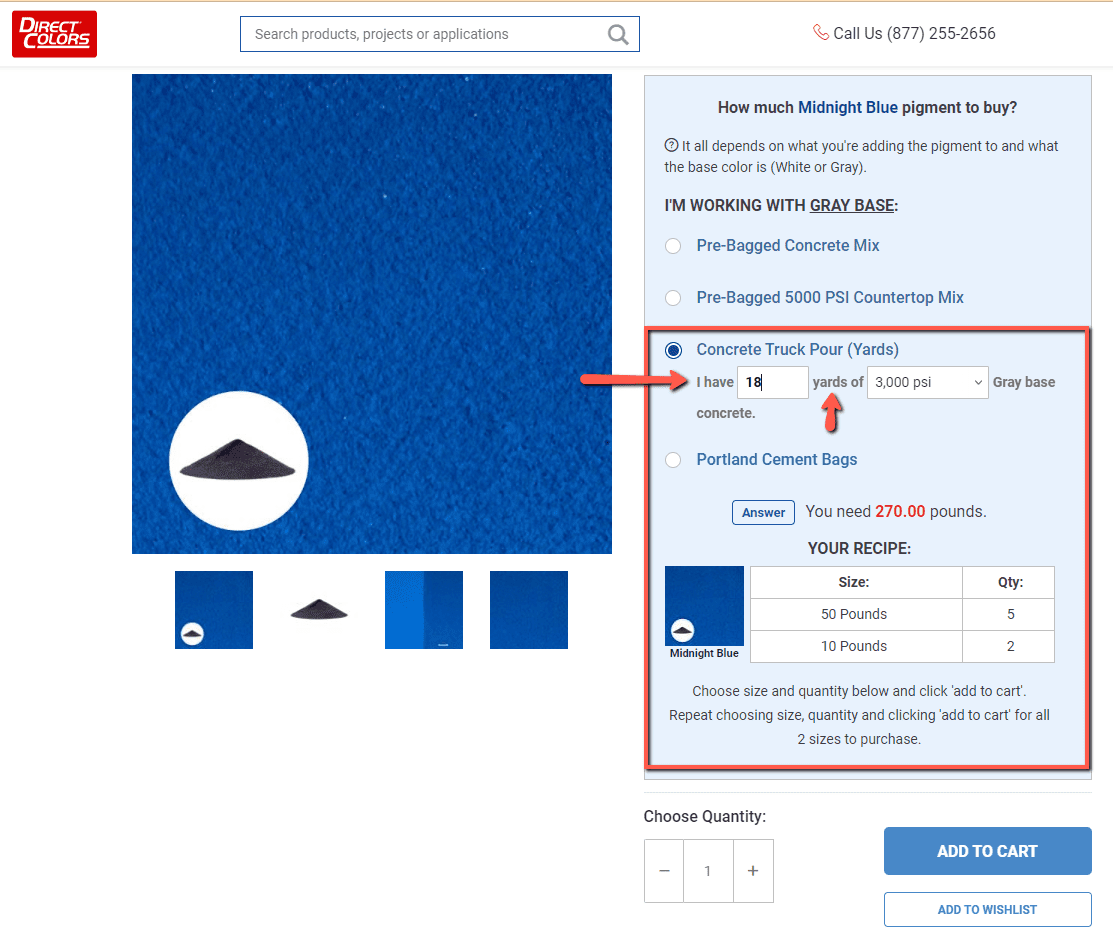

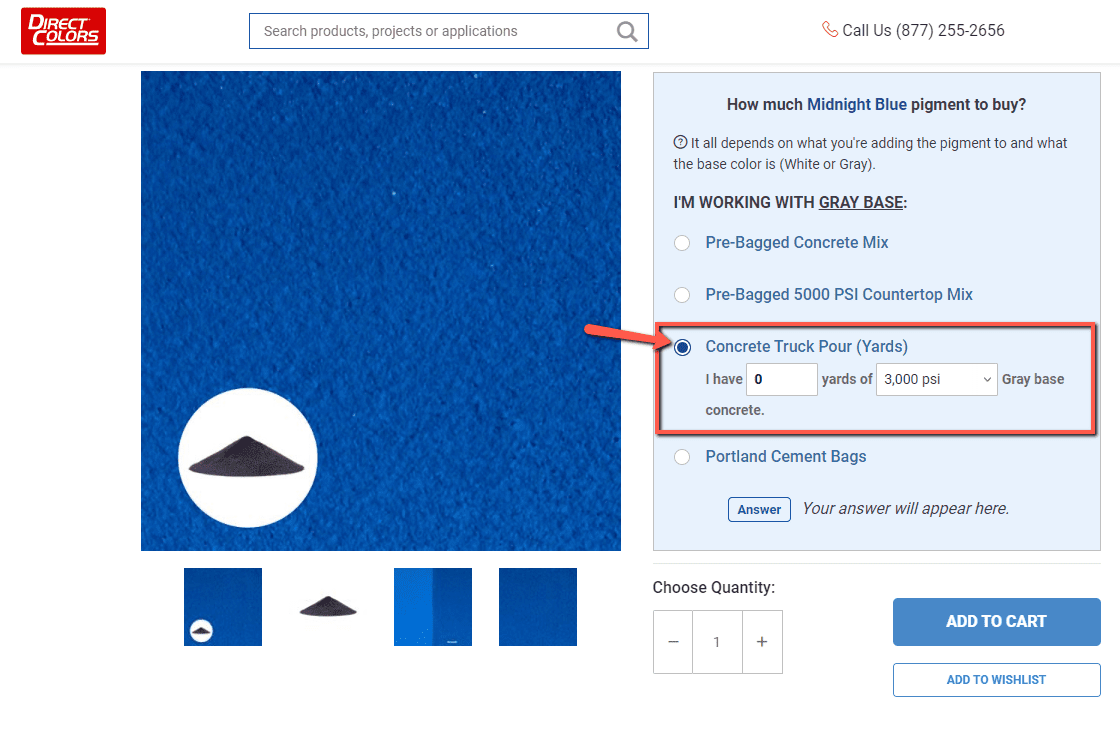

Now, use the Direct Colors’ Truck Pour Per Yard Pigment Calculator to determine exactly how much pigment is required to integrally color your slab.

How Does PSI Affect Concrete Color?

The higher the PSI of the cement being poured, the more pigment is required to achieve the projected colors found on the Direct Colors Color Chart.

How Much Fly Ash Is in My Concrete?

Fly ash is added to ready-mix cement by the concrete manufacturer in place of cement at a substitution rate commonly between 15-40%. While there are structural benefits of adding fly ash to concrete, a higher rate of fly ash results in a lighter final appearance of the concrete slab which makes predicting color more difficult.

For the most accurate integral concrete color, choose ready-mix cement with around 10% fly ash, and no more than 20%.

How Many Yards of Concrete will be Poured?

The number of yards of poured concrete determines how many pounds of pigment will be needed to achieve a specific color from our color chart. The same amount of pigment and water should be added to each truck to control for color variation if more than one truck is involved.